|

Our Safety Data Sheets for all chemical reagents are available by request by sending an email to support@dtkwater.com.

|

|

Our Safety Data Sheets for all chemical reagents are available by request by sending an email to support@dtkwater.com.

|

|

KEY FEATURES |

|

|

|

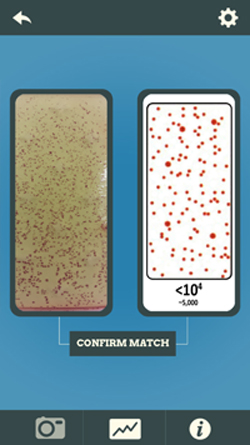

DIPSLIDE COMPARATOR APP DTK Water have developed a free unbranded app to allow the easy comparison of your dipslide result to known standards when using the DTK Water range of dipslides. Using smartphone technology, the app allows users to take pictures of their dipslides and catalogue them for separate sample sites, save results in graph format and email results showing a picture of the dipslide. The app also holds an information page displaying details on dipslide use, dipslide disposal, interpretation of results and more. Available for free via the apple and android stores. |

|

|

KEY FEATURES

|

|

|

UNIVERSAL RAPID LEGIONELLA TEST KIT The Universal Rapid Legionella Test kit is a breakthrough in technology from Hyrdosense for the rapid detection of legionella bacteria in industrial water. Test results can be obtained in minutes instead of days. The industrial legionella kits provides the user:

The test kit contains all the items required to perform 5 tests – including filters, recovery buffer, collection vessel and sample point. LEGIONELLA CONTROL This Legionella field test kit uses immunochromatographic assay, to detect the presence of cell surface antigens from Legionella bacteria in a sample. The presence of antigen causes the ‘Test Line’ to turn red in colour. A ‘Control Line’ is included which should always turn red if the test has been performed correctly. These tests are optimised for use with industrial water systems, cooling towers and whirlpool spas. The filtration step needs no pumping, just connect the sample point to the water system and use the system pressure to drive the filtration. The test follows a simple procedure and the results easily obtained within 30 to 35 minutes. Once the result is obtained the treatment engineer can asses the water condition and complete any treatment necessary to ensure there is no risk of out breaks and subsequent litigation. |

|

|

TEST KIT & INSTRUMENTS

|

REPLACEMENTS

|

|||||||||||||||||||||||||||||||||||||||

|

PRODUCT DETAILS |

||||||||||||||||||||||||||||||||||||||||

| Bacteria detected | Legionella pneumophila serogroup 1 | |||||||||||||||||||||||||||||||||||||||

| Detection method | Lateral flow immunochromatographic assay | |||||||||||||||||||||||||||||||||||||||

| Lower limit of detection | Down to 100 CFU/L (0.1 CFU/mL) | |||||||||||||||||||||||||||||||||||||||

| Specificity | Tested against a wide range of waterborne bacteria, including Acinetobacter calcoaceticus, Aeromonas hydrophila subsp. hydrophila, Bacillus subtilis, Burkholderia cepacia, Citrobacter freudii, Citrobacter koseri, Escherichia coli, Enterobacter cloacae, Klebsiella oxytoca, Pseudomonas aeruginosa, Pseudomonas fluorescens, Pseudomonas putida, Pseudomonas stutzeri, Ralstonia pickettii, Raoultella terrigena, Streptococcus pyrogenes, Yersinia ruckeri. No cross reactions observed at concentrations > 109 CFU/L.Staphylococcus aureus has been observed to cross react with the test at concentrations > 108 CFU/L.Legionella pneumophila serogroups 4 & 7 cross react with the test at concentrations >109 CFU/sample. The test does not react with any other L. pneumophila serogroups or L. species tested. |

|||||||||||||||||||||||||||||||||||||||

| Test volume | 100 μL | |||||||||||||||||||||||||||||||||||||||

| Suggested sample volume | 250 mL | |||||||||||||||||||||||||||||||||||||||

| Sample parameters | Sample should filter in less than 10 minutes. | |||||||||||||||||||||||||||||||||||||||

| Biocides | The product has been tested with a range of common biocides and iodispersants used in Legionella control, at their normal maximum perating concentration. Active ingredients tested include: lutaraldehyde, didecyl-dimethyl-ammonium chloride, isolthazoles, dibromonitrilopropionamide, ionic and non-ionic surfactants. The test gives a false positive if used with polymeric biguanide or THPS. |

|||||||||||||||||||||||||||||||||||||||

| Operator time | 5 – 10 minutes |

|

SystemSURE™ Plus is the next generation system of the world’s best-selling ATP hygiene monitoring system. With improved functionality, new software, and increased memory, the SystemSURE™ Plus meets the demands of the largest and smallest companies around the world. |

|

START CLEAN & STAY CLEAN A clean environment is key to producing safe, quality foods. By incorporating ATP monitoring into preoperative equipment inspection and change-over cleaning verification, quality personnel can verify equipment cleanliness in seconds. Your facility is only as clean as you start, so it’s best to start the day right. |

|

PROVEN PERFORMANCE The SystemSURE™ Plus line of ATP monitoring systems has been used by food and beverage processors for over 10 years. Not only are they designed to last, but more importantly, to perform better than all other systems on the market. WORK MORE EFFECTIVELY When you set up your ATP monitoring program, you will determine where and when testing should occur. The SystemSURE™ Plus makes it easy to manage all your test locations by storing up to 251 locations in an organized group called a Test Plan. When you’re ready to test, simply select the Test Plan that corresponds to the area, equipment, or day, and the SystemSURE™ Plus will bring up all the locations you need to test in that plan. MINIMAL SIZE, MAXIMUM DURABILITY |

|

The SystemSURE™ Plus is designed for convenient, single-hand use to make using the system and navigating the menus easy for every user. Don’t let the petite shape fool you – SystemSURE™ Plus makes no compromises when it comes to durability. The rugged outer shell and splash-proof keypad keep SystemSURE™ Plus Plus safe in the harshest environments. For extra protection, every system comes with a complimentary carrying case with a shoulder strap for hands-free transportation to test locations in your facility. |

|

|

IMPROVED TECHNOLOGY SystemSURE™ Plus uses a state-of-the-art Photodiode sensor technology that enables superior sensitivity and stability over bulky Photomultiplier Tube (PMT) sensors. This tiny sensor allows our device to be smaller, lighter, more durable, and longer lasting than systems using a large, fragile PMT sensor. |

|

|

EASY CALIBRATION Built in sensor checks and a Calibration Control Kit sold separately make verifying calibration effortless. Simply turn on the self-check feature and every time the system is powered on, calibration will be confirmed. With the internal self-check and the calibration kit, you’ll always be confident the system is within specifications. In addition, you’ll avoid costly and inconvenient yearly calibration charges that other manufacturers require. |

|

|

COMPATIBLE TESTS

|

|

ORDER CODES

|

TECHNICAL SPECIFICATION

|

|

Our high quality drop test kits and reagents are available in a wide range of parameter specific options to suit many analytical requirements. Each self contained kit is housed in its own rugged carry case and comes complete with all necessary equipment such as waterproof instructions, reagents, syringe and test bottle or test cell. Replacement reagents are listed under each parameter which can be purchased to ensure continued analysis. |

|

|

DROP TEST KITS & REAGENTS The following list of reagents are for use in various water testing applications including Potable, Process, Industrial Boilers & Cooling Systems, Swimming Pool and Waste Water treatment. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note: Ranges vary and are dependant on the sample size used to carryout the test, for more information please read the instructions. |

|

KEY FEATURES

Note: Range is dependant on measuring instrument used. |

|

|

BOILER MONITORING KIT The DTK comprehensive Boiler Test Kit has been developed specifically for engineers and treatment professionals responsible for the maintaining and management of boiler systems. This test kit has been designed to include the key parameters which enable the monitoring of samples in these water systems ensuring optimum operating conditions are maintained. The kit provides accuracy and speed, utilising drop test and comparator reagents together with electronic meters for the most efficient monitoring of water samples. The reagents and equipment are specified below. The BTK001 is supplied in a robust carry case with reagents and instruments secured by a high quality chemical resistant foam insert with sufficient chemical reagents to carry out between 100 and 200 tests. INDUSTRIAL WATER TREATMENT Boiler water systems and boiler feedwater systems require regular and careful monitoring to ensure the correct water conditions are maintained within an approved treatment programme. Any failure to maintain the correct levels and dosing of the chemical treatments can lead to:

These can lead to unstable water conditions with potential negative consequences to the life of the plant and operating costs. |

|

|

TEST KIT & REAGENT CODES

|

|

|

PRODUCT BENEFITS DTK Microbiological tube tests offer an affordable way to test for Nitrite reducing bacteria (NRB) or Sulphate reducing bacteria (SRB) without the need of laboratory facilities. The NRB/SRB tube tests are user friendly with easy to follow instructions. Preliminary results are available within 24 hours. The tests can be used as an indicative measure for field based decision making purpose. |

|

DTK Water manufacture NRB & SRB Tube Test for use in monitoring microbiological levels. Our company has in the past purchased similar products from ECHA Microbiology Ltd and sold them under their registered trade mark SIG Test®. Subsequently DTK Water inadvertently also marketed our Tube Tests as Sig Tests® and we now wish to confirm that our NRB & SRB Tube Tests are not related to ECHA Microbiology Ltd and are not associated with or covered under the ECHA Ltd registered trade mark SIG Test®. |

|

KEY FEATURES |

|

|

|

|

INCUBATION OF DIPLIDE TESTS Dipslides are used to establish and asses if the conditions present in a water system encourage bacteria to multiply. Once the sample has been collected the dipslide requires incubation at 30 °C for 48 hours to obtain a true result and consistently time after time. A dipslide incubator is a critical element of microbiological monitoring. A lower temperature can mean the bacteria will grow more slowly and give a false low reading. If your reading is artificially low then the treatment engineer will consider that no action is necessary and the bacteria will be free to multiply and increase the risk to public health. Conversely if the temperature is high then the growth may be accelerated giving a false positive. This false high bacteria count can lead to unnecessary and expensive extra cleaning and treatment processes. Approved code of practice and guidance for the control of legionella bacteria in water systems requires weekly monitoring of microbiological activity. GNAT INCUBATOR The Gnat Incubator has the capacity to incubate two dipslides at a preset temperature of 30 °C. The two heated dipslide cells will hold standard MicroSlide Dipslides or non-screw top dipslides. This compact 2 dipslide Incubator has been designed with industry standard heating technology to meet the incubation required for L8 legionella control monitoring. It is specifically intended for those treatment engineers who have a routine requirement to monitor a single cooling tower. There is no confusing set up as the incubator is factory set to 30 °C, just plug it in and switch it on. It will be at 30 °C in 30 minutes. Running on the supplied 220 / 240 V mains power lead or an optional 12 V power lead for use in a standard car lighter socket, it is protected by an internal fuse and has an over-temp protection for safe extended use. Simplicity of operation, maintenance free, 30 minute minute warm up period, the incubation of your dipslides couldn’t be easier! |

|

|

ORDER CODES

|

TECHNICAL SPECIFICATION

|

||||||||||||||||||||||||||

KEY FEATURES

|

|

CONDUCTIVITY STANDARD SOLUTIONS

|

|

|||||||||||||||||||||||||||||||||||||

|

Note: Ranges vary and are dependant on the sample size used to carryout the test, for more information please read the instructions. |